Home beer brewing

Eastern 2019

(2019-04-21)

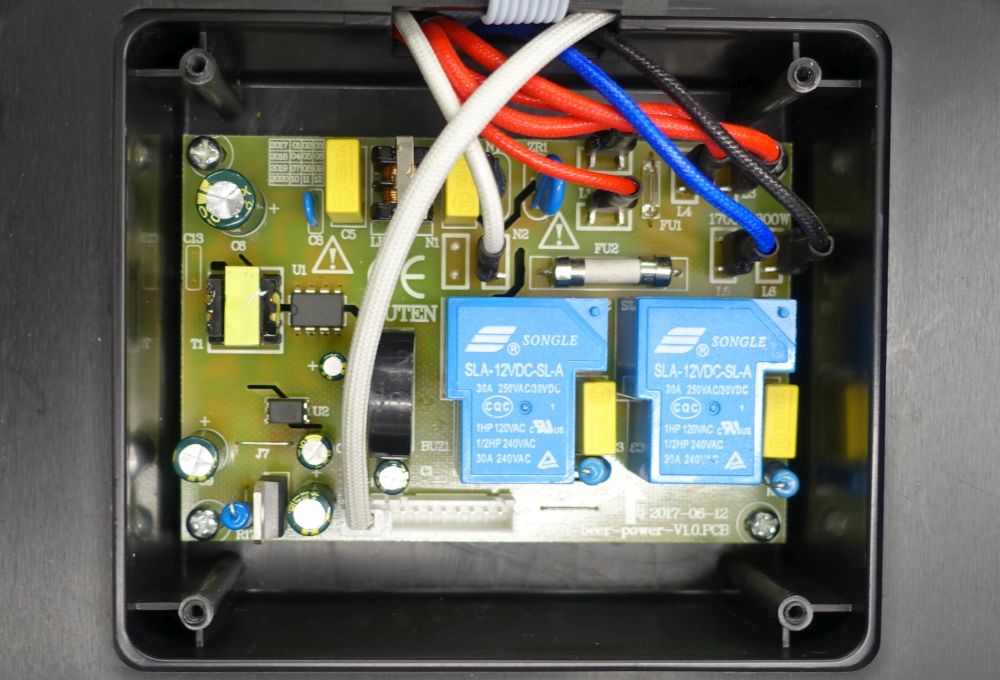

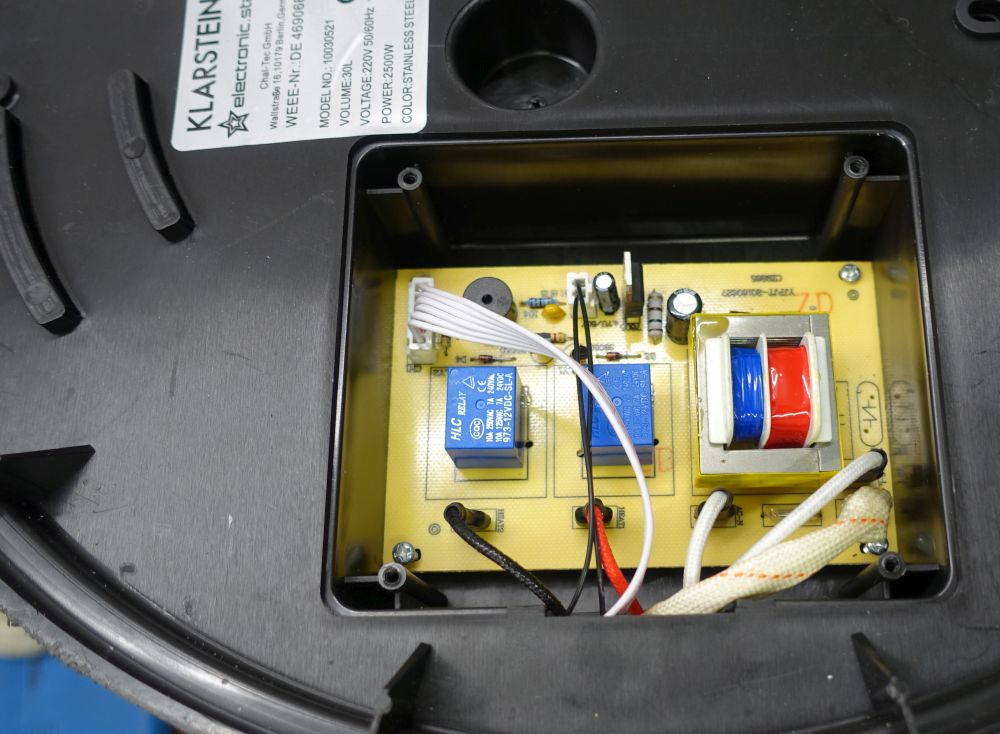

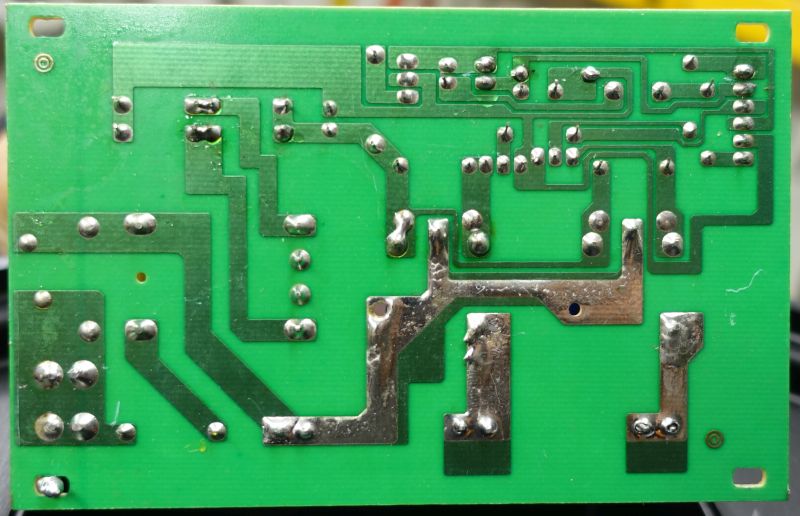

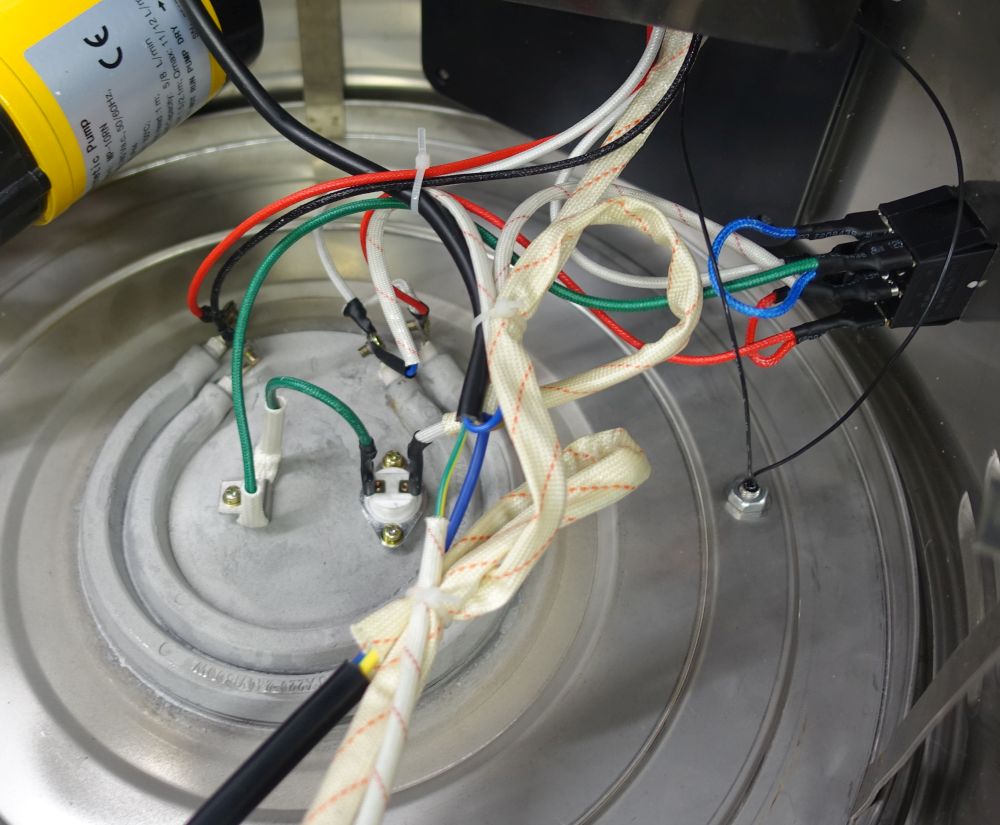

Klarstein Mundschenk Version Radow 1 - 2018

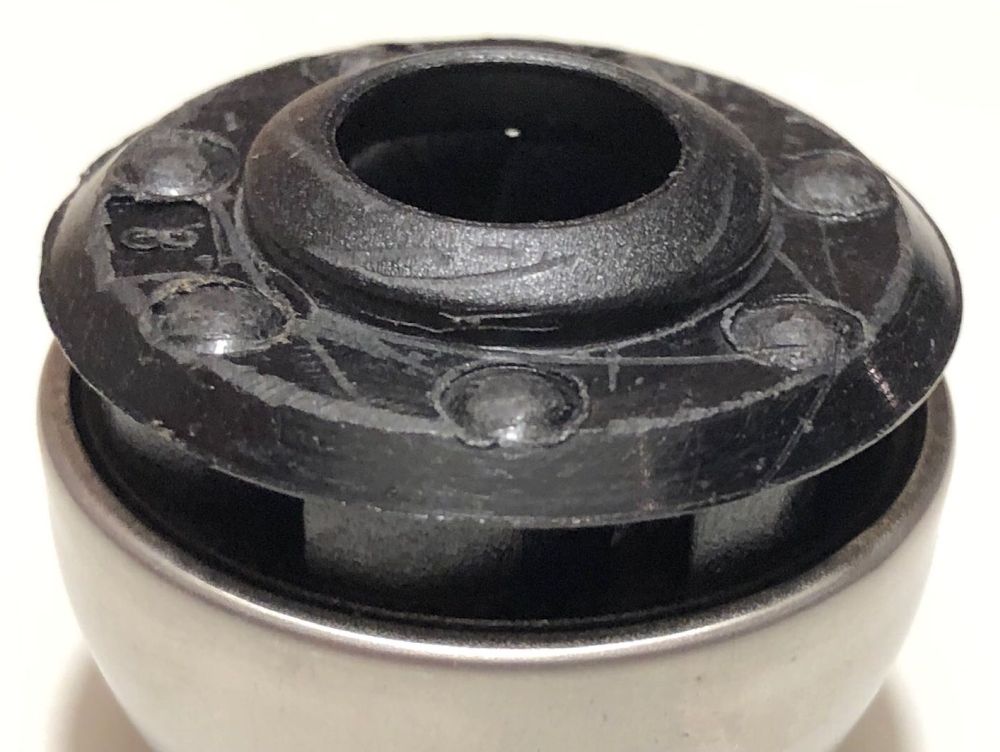

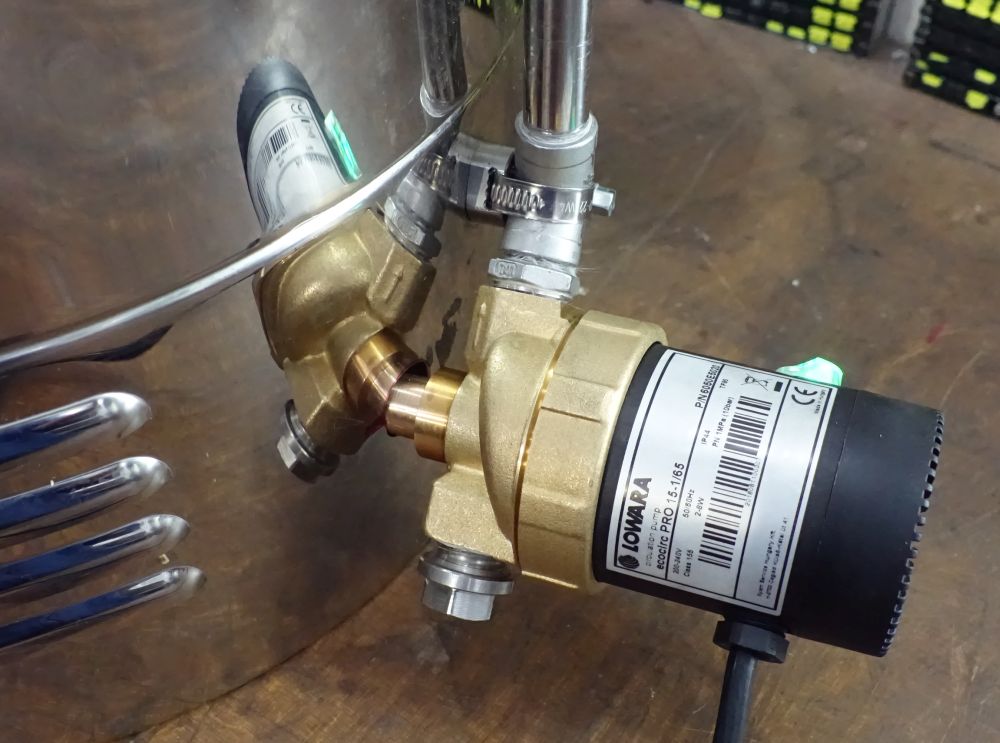

Sud-Pumpe (2018-12)

Klarstein Mundschenk Version Radow 1 - 2018

My first chocolate beer (2018-09)

Hier kommt noch das Rezept hin.

http://meinsudhaus.de/bier-rezepte/obergaerige-biere/schokoladenweizen/

Brauen bei Hagel und Sonnenschein ©Radow 2018-09-24

Filling the chocolate beer

Before bottling, it´s always time to "clean bottles!"

Letzte Waschung mit Starsan vor der Befüllung ©Radow 2018-10-02

Fortunately, the 20x 0.3 liter Flensburger box fits completely in the sink. After the interior flushing with the yellow bottle washer, the bottles can drip headfirst in the box without any spills on the kitchen flor.

Then they are provided for bottling. The now germ-free rubber should not lie on the possibly still outside dirty bottle when waiting.

Gewaschene und entkeimte Flaschen warten auf das Schokoladenbier ©Radow 2018-10-02

Flaschenabfüllung per Schwerkraft ©Radow 2018-10-02

Result: 55 bottles of 0.3 liter chocolate beer - let´s get over it in some weeks!

Approximately 1 cm thick dregs in the 30 liter fermenting keg

Klarstein Mundschenk Version 2 - 2018

Klarstein Mundschenk Version 1 - 2017

Brewing in the preserving cooker - 2016

Fermentation Box v1 - 2016

Erstes CO2 entweicht - die Hefe arbeitet!

How everything began - 2016

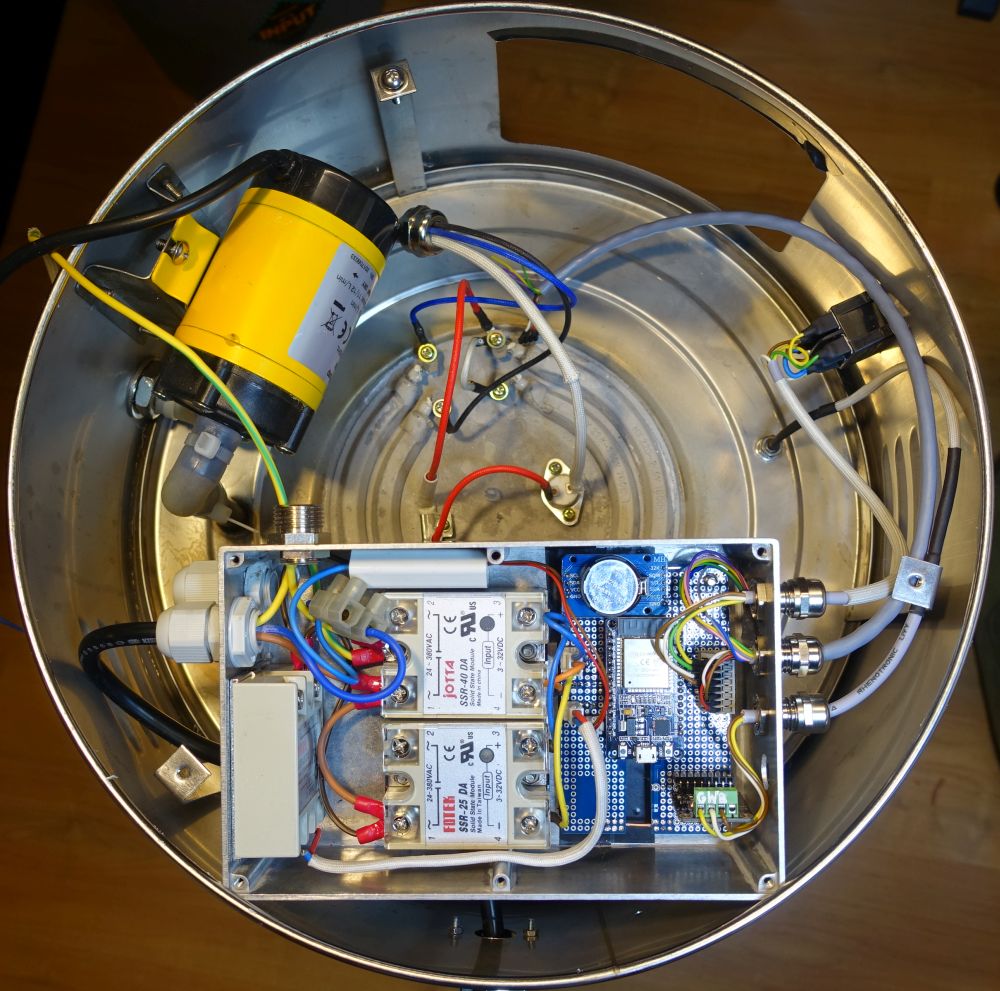

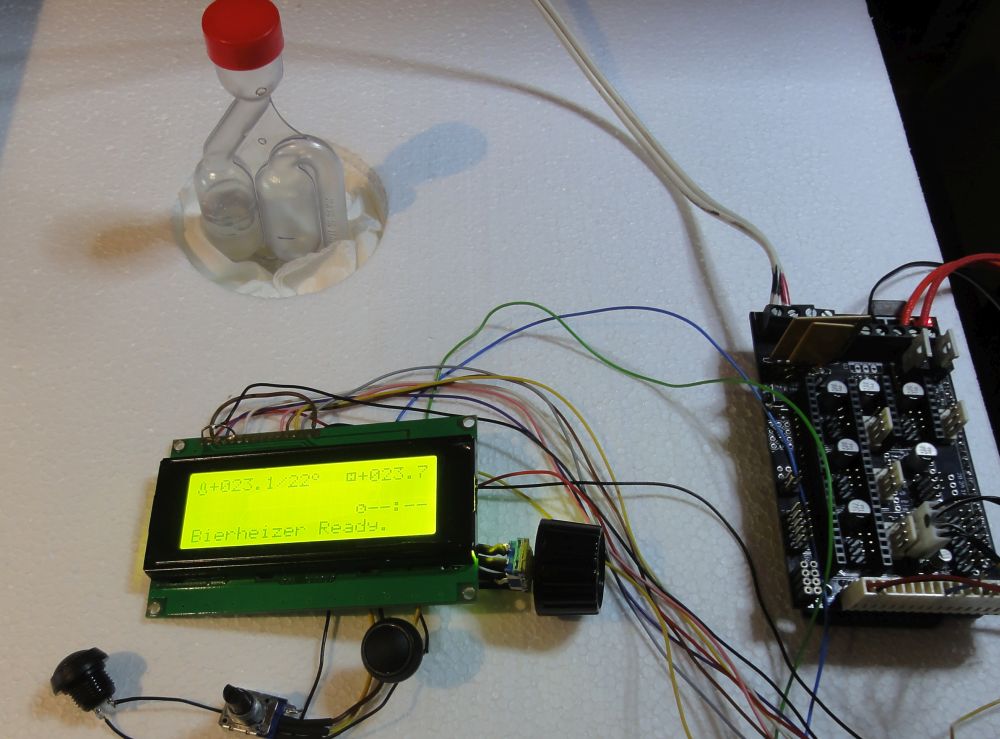

In 2016, we had developed the idea of brewing beer in the Arduino Hannover Group and / or to develop a brewing control. The combination of the topics brew kettle, piping, sensors, agitator, pumps etc. and their control with the Arduino inspired me immediately. As a casual wheat beer drinker, the technology was for me in the foreground.

Coincidentally, you could visit the small brewery "Das Freie" (The Free) on the estate Rethmar on 04.09.2016 as part of the Region Discovery Day Hannover. There I saw my first hop and was allowed to taste malt grains.

Hops, malt and the malt pipe of a 50 liter Speidel brewer of the Craft Brewery "Das Frei" (The Free)

Of course, the press is not far away when it comes to leisure and beer. Patiently Rejnold and I posed for the camera, while the experts explained the basics of brewing. In our local newspaper the photo below was taken in the article "Look brewers in the kettle" with the subtitle "Stephan D. (right) shows the future hobby brewer Rejnold B. (left) and Rainer Radow, how the sugar content can be measured" published. From that day on my colleagues kept asking for the first homebrew ...

Visit of the Craft Brewery "Das Freie" (The Free) on an estate in Rethmar near Hanover

Source Photo: HAZ 2016-09-04

That there are so many different malt varieties, I had not known until this day. To the skills of the maltsters you can only pull the hat. It is they who allow the brewing of so many different types of beer.

Malt selection from the delivery program of the German malting Weyermann

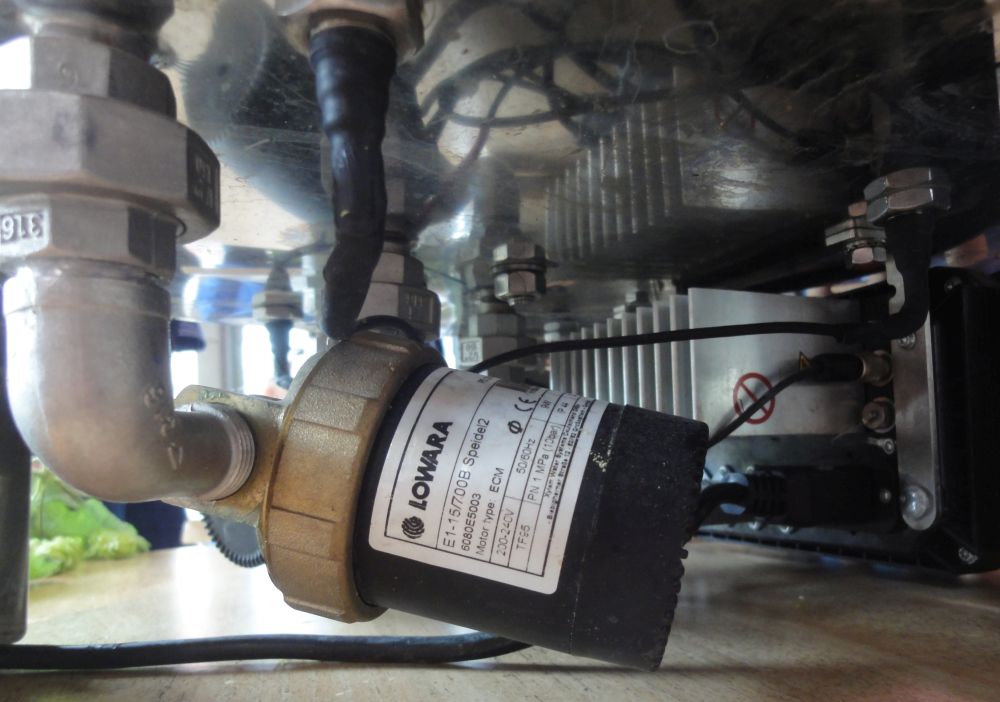

Naturally I was particularly interested in the "small" 50 liter Speidel Brewmaster kettle. With it the people of "Das Freie" brewed their first batches. The open and very tidy design of the boiler allows deep insights. There are two pumps that ensure a good circulation when brewing. Due to the combination of pumps and the malt pipe principle, it is not necessary to stir the Speidel during brewing. A temperature sensor in conjunction with a microprocessor control ensures a controlled brewing process. The Speidel boilers are characterized by a high quality of workmanship. The 20 liter device is 2018 in the basic configuration at about 1,600 euros.

Speidel Brewmaster 50 l from below. One of the two bottom pumps at the front, the heat sink of the controller at the back

In the brewhouse of "The Free" you will find of course a larger Speidel, but this works on the same principle. Since the malt pipe in these dimensions can no longer be lifted by hand from the brew, there is a crane for this purpose. The further advantage of this is that you can draw the malt tube out of the brew very slowly and thus prevent unwanted compression of the natural filter layer that forms through the malt.

Brewhouse of "The Free" - 2016

At the end of this day I was sure. "I also want to build such a brew system!"